How To Locations A/t Clutch Pressure Control Solenoid On Acura Mdx 2014

Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: 2005 Acura MDX

- Issue: No move to incorrect gear starts

Little did the possessor of a 2005 Acura MDX know that at the fourth dimension the transmission in his vehicle was existence repaired that it was the start of a long uphill battle. The vehicle initially was towed into a store for inspection due to a no-movement condition. In addition, the bank check-engine light was on indicating the presence of trouble codes, several of which were verified on a scanner.

The MDX was equipped with a 3.5L engine and 5-speed automatic transmission and had 118,000 miles on it. Despite the trouble codes, the engine ran well and the vehicle was withal in pretty practiced shape so it was decided to peel downwards the manual to determine the extent of damage. As expected, there was substantial impairment internally that require replacement of several hard parts. Due to the debris that was generated, several electrical components were replaced as well. The transmission was rebuilt and reinstalled with the hope that everything would piece of work great. Unfortunately, such was not the case.

The situation started to deteriorate the instant that the transmission was placed into gear since information technology did not perform as expected. Regardless whether the transmission was placed into bulldoze or opposite, as soon every bit the wheels started to plow the engine would lug down as if the lockup torque converter was starting to utilise. Beyond that, in drive the transmission did not take off in first gear but rather a college gear such every bit 4th or 5th and of course the cheque engine calorie-free came back on. The symptoms seemed to be erratic to boot. Although the initial rebuild took a fair amount of time to consummate due to parts availability, etc., information technology was simply the offset of a long journeying.

After assessing what the symptoms were the diagnostic process began and various systems and components for either checked or inverse but, to no avail. Finally, the focus turned to the PCM and although it was re-flashed previously, the conclusion was made to effort another. Replacing the PCM just fabricated matters worse, and by this fourth dimension store personnel were running out of gas, so the vehicle was sent to a Honda dealership.

Once at that place, a Honda technician went through their diagnostic procedures and decided to put the original PCM back into the vehicle in club to return to square one, equally bad as that was. With the original PCM dorsum in the vehicle, the technician reevaluated the situation and adamant that the transmission was bad and needed to be replaced. By this time non only were the costs mounting up but so was the time that the customer was on shoe leather. Finally, a command decision had to be fabricated, and the owner of the vehicle was the one that made information technology, which was to take information technology to a 2d repair facility and start from scratch.

Due to the vehicle's history, store No. 2 decided to remove the manual and completely disassemble it in order to inspect each component. Aside from replacing a couple of items with marginal wear, the new technician decided to install a valve body kit to address the potential lockup event which is predominant on many Honda transmissions, but as a precaution. All components were either inverse or tested and the unit was reassembled. Electrical components were not changed at the time since all of them were accessible externally, in the issue one was found to be defective after the route test. With the manual back in the vehicle, the engine was fired up to see if the latest repair attempt was successful or not.

Initially, things were looking upwardly since the engine did not chug with the transmission in drive or reverse nor were in that location whatever check engine lights on; however, when the technician tried to drive downward the route he noticed that the unit was not in first gear. The transmission did have a start gear start manually.

At this betoken a scanner was hooked upwardly to verify the correct computer indicate as well as to individually test solenoid office and everything seemed to exist OK. After reviewing the solenoid firing gild, the shift solenoids were removed to determine if there was an issue with operation or design. After a closer examination, two of the 4 solenoids were found to exist incorrect.

Unfortunately, when the rebuilder at the original shop was replacing the array of bad parts, he chose to purchase replacement shift solenoids from a reman facility instead of getting new ones from a distributor. The replacement solenoids were actually from a afterwards model MDX, which wait well-nigh identical to previous models which of course is no shock when it comes to Honda manual components. This state of affairs illustrates the importance of "expect before you jump" when replacing stuff in Honda transmissions.

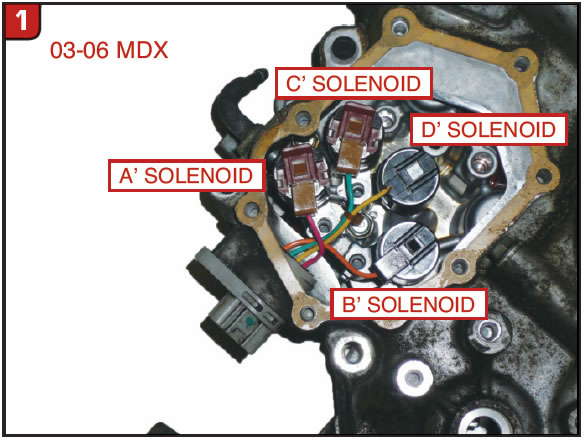

When Honda redesigned the MDX transmission in 2003, the shift solenoids were relocated internally however they were attainable externally, which was a plus (Figure 1).

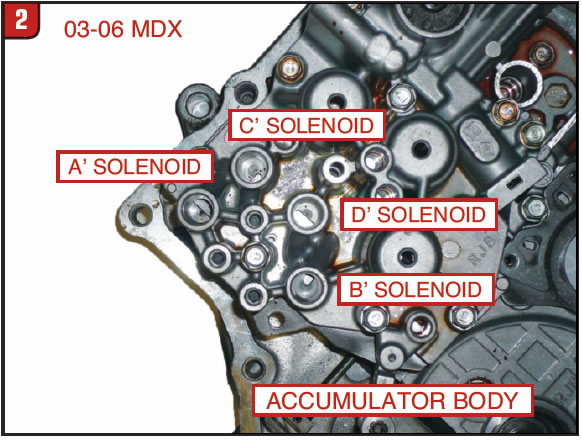

With the linear A/B solenoids and support plate removed, all four shift solenoids are exposed, two brownish connector and two black connector designs. The solenoids are bolted to the accumulator valve body, which is attached to the bell housing, (Figure 2). The brown connector solenoids are toward the top of the valve body with the blackness connector solenoids toward the bottom. The instance connector wire terminals are likewise chocolate-brown and black accordingly.

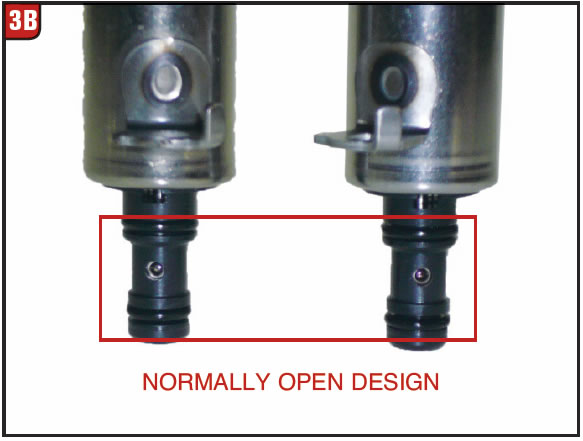

The brown and black connector solenoids used for MDX from '03 to '06 were basically the aforementioned in advent and operation (Figure 3A). All four solenoids are NO (normally open) with argent colored housings and a comparable barrel design. A close-up of the orifice holes is one way to make up one's mind if the solenoid is unremarkably open up (Effigy 3B). The color of the harness wire should always be recorded during disassembly to avoid problems downwards the road.

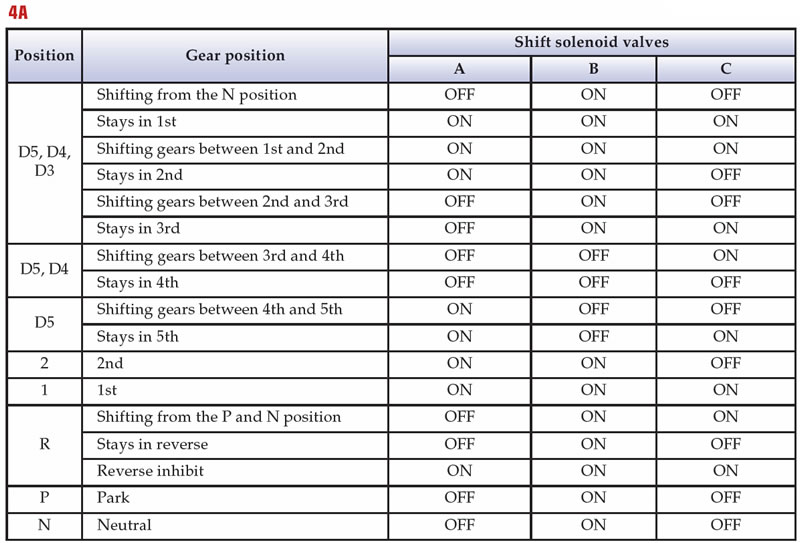

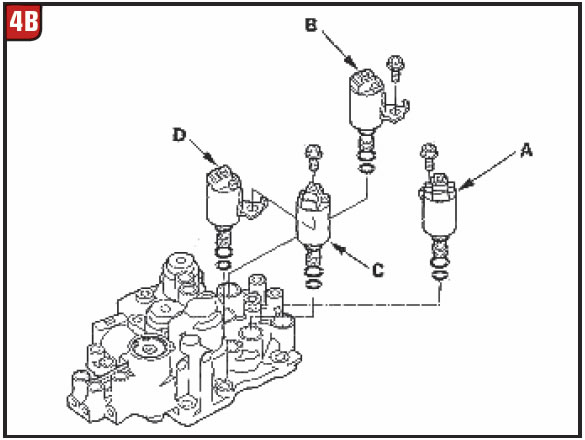

The solenoid firing order for a '03 to '06 MDX is unique to those models (Effigy 4A). The actual shift solenoids are coded as A, B &C with the lockup solenoid coded every bit D, although it is omitted from the solenoid functioning chart. The lockup solenoid tin can exist operated under various conditions.

It is also important to not merely know where a brown or black connector solenoid should exist only, to know which letter that the solenoid is for diagnostic purposes considering all models are not created equal (Figure 4B). The accumulator body illustrated is somewhat upside down resulting in the two brown solenoids (A & C) being below the two blackness solenoids (B & D) therefore, verify all positions earlier replacing any solenoid.

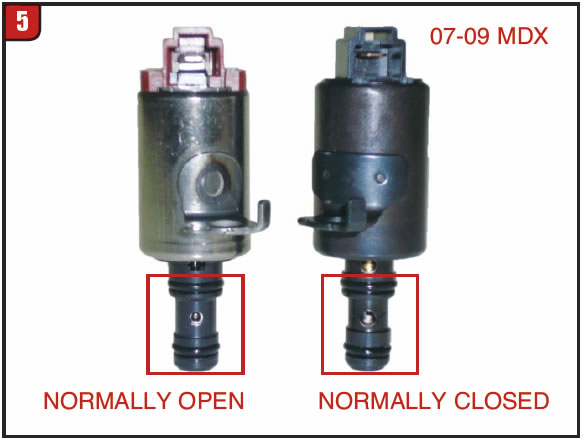

The chief culprit in this scenario was the black connector solenoids that the starting time rebuilder received from the reman facility. The builder did not realize that the solenoids he received were for '07-upwardly MDX models. For some reason Honda decided to change only the black connector solenoids in 2007 to a NC (normally closed) blueprint without drastically changing the physical appearance. The brown solenoid part number remained the same for later models (Figure 5). 1 style to tell the divergence in pattern is by the orifice pigsty in the barrel. The brown solenoid on the left has a slightly smaller orifice hole than the NC blackness connector solenoid on the right and the O-band positions are slightly different. In add-on, the new design solenoids accept a black body, not silver.

Part numbers:

- Brown connector ('03-09) 28400-RDK-003

- Black connector ('03-06) 28500-RDK-003

- Black connector ('07-09) 28500-RJB-004

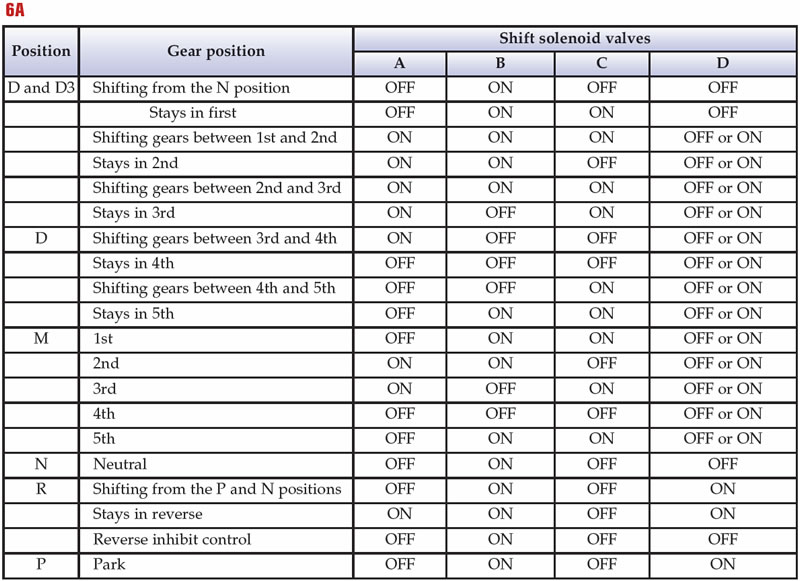

Beyond the concrete differences and to make matters worse, the solenoid firing guild was inverse in 2007 (Figure 6A). When doing diagnosis on MDX or for that matter whatever Honda, always refer to the appropriate charts to avoid chasing ghost. At least the later model chart includes the lockup (D) solenoid operation different the chart for previous models.

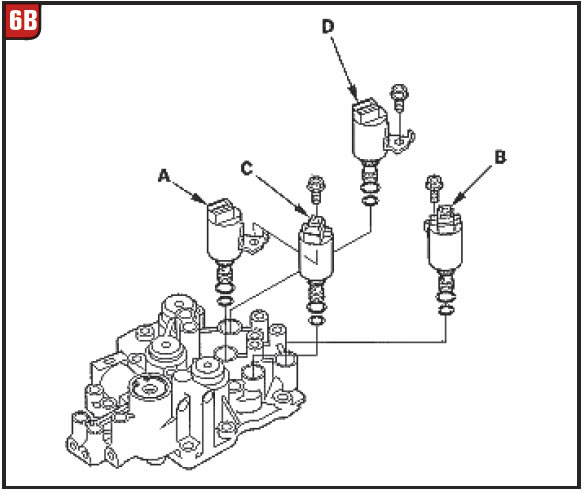

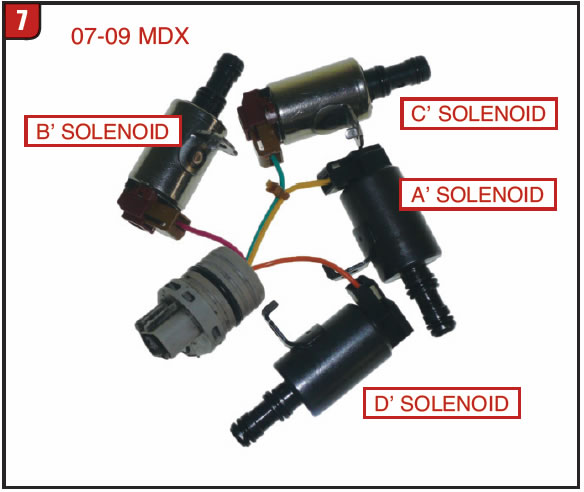

Another slight contraction that occurred between models had to do with terminology. Although early and late models all employ two brownish and 2 blackness solenoids, the letter designation was inverse in relation to solenoid position (Effigy 6B). When dealing with '03-06 MDX models refer to solenoid position chart in Figure 4B and use the chart in Figure 6B for '07-09 MDX models.

Lastly, regardless of awarding make sure to connect the right harness wire to each solenoid to avoid whatever issues (Figure 7). The electrical case connector and harness wire colors are the same for 2003 upwardly MDX models; just the names were changed to protect the innocent.

How To Locations A/t Clutch Pressure Control Solenoid On Acura Mdx 2014,

Source: https://www.transmissiondigest.com/acura-mdx-with-a-mind-of-its-own/

Posted by: strothersinquen.blogspot.com

0 Response to "How To Locations A/t Clutch Pressure Control Solenoid On Acura Mdx 2014"

Post a Comment